LED display technology evolves rapidly, yet maintenance remains central to operational longevity. Standard LED modules offer conventional rectangular panels with predictable service routines. In contrast, creative LED display modules deliver flexible, dynamic shapes and unconventional structures. These modules bring higher visual impact but introduce unique maintenance challenges. Understanding these differences is crucial for facility managers, rental companies, and digital signage operators. Effective maintenance ensures reliability, reduces downtime, and protects investment in high-performance visual systems.

Standard LED modules typically consist of fixed pixel grids on rigid PCB panels. The design emphasizes ease of installation and uniform performance. Maintenance routines focus on module cleaning, pixel inspection, power supply verification, and signal continuity. Because the panels are uniform and widely adopted, most technicians have experience with replacement protocols and repair workflows. Components such as LEDs, IC drivers, and connectors are standardized, reducing the learning curve for maintenance teams.

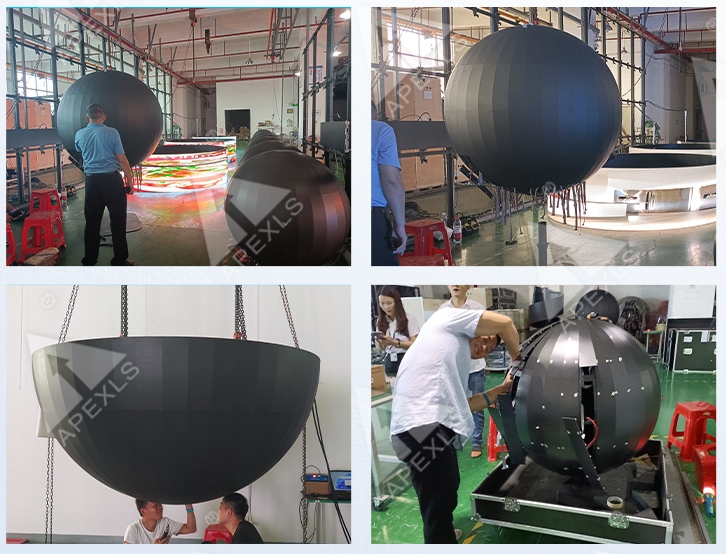

Creative LED display modules depart from traditional shapes, embracing curves, spheres, cylinders, and custom geometries. These modules integrate multiple pixel densities and flexible circuits to support 3D, 360° visual effects. While the result captivates audiences, the modular complexity introduces higher maintenance requirements. Technicians must account for structural alignment, custom connectors, flexible cabling, and specialized control systems. Unlike standard modules, creative designs demand precise handling to preserve both visual performance and physical integrity.

In standard LED modules, rear-service access is common. Technicians can remove panels from back cabinets with minimal disruption. This approach simplifies routine checks and reduces service downtime. By contrast, creative LED display modules often rely on front-service or hybrid access due to unconventional layouts. Removing a panel may require partial disassembly of the surrounding structure. While front-service access increases operational flexibility, it demands careful alignment and protective measures to prevent damage to adjacent modules.

Cleaning standard LED modules typically involves wiping surfaces, using compressed air, or vacuum-assisted dust removal. The flat, uniform surface minimizes the risk of residue accumulation. Creative LED modules feature curves, edges, and overlapping pixels, which collect dust and debris more readily. Maintenance teams must adopt specialized tools and techniques, such as soft brushes, micro-vacuum heads, and controlled humidity environments. Regular cleaning intervals are more frequent for creative modules to prevent dust from affecting pixel clarity and visual uniformity.

Standard LED modules often use direct, linear wiring with minimal routing complexity. Signal and power lines follow predictable paths, enabling quick fault isolation. Conversely, creative LED modules employ flexible circuits, multi-directional connections, and sometimes wireless synchronization between panels. Diagnosing issues requires advanced testing equipment, knowledge of signal flow in irregular geometries, and careful handling to avoid cable fatigue. Maintenance schedules include both electrical checks and visual inspections to ensure uninterrupted performance.

Pixel failure in standard LED modules is usually isolated and predictable. Replacing an individual pixel or module restores uniformity efficiently. Creative LED modules, especially high-density or curved designs, may experience localized stress that affects multiple adjacent pixels. Maintenance must account for thermal expansion, mechanical tension, and signal interference. Technicians use specialized software for pixel mapping, remote diagnostics, and calibration to maintain visual consistency. These extra steps prolong service duration but preserve high-quality output.

Outdoor standard LED modules often face UV, moisture, and temperature fluctuations. Their rectangular design allows easy weatherproofing with standard enclosures and gaskets. Creative modules introduce complex surfaces that challenge waterproofing and heat dissipation. Maintenance includes checking seal integrity at curves, edges, and junctions. High-traffic or exposed installations require routine inspections for mechanical stress and mounting integrity. Proactive preventive maintenance reduces the risk of performance degradation under harsh environmental conditions.

Both standard and creative LED modules rely on control software for signal processing, calibration, and synchronization. Standard modules often integrate with widely used platforms and protocols. Creative modules may employ proprietary or custom control software, particularly for dynamic shapes and 3D visuals. Maintenance teams must perform firmware updates, calibration routines, and system diagnostics more frequently. Monitoring software logs and visual alignment ensures that creative installations maintain their intended effect without visual artifacts.

Standard LED modules offer predictable maintenance costs due to widely available parts and simplified workflows. Creative LED modules often involve higher labor intensity, more specialized tools, and longer service intervals. While the initial investment in training and equipment increases cost, proactive maintenance reduces long-term downtime. Facility managers must balance visual impact with maintenance feasibility to optimize operational efficiency.

For standard modules, preventive maintenance includes routine cleaning, power checks, and environmental monitoring. Corrective maintenance is straightforward, often involving a module swap. Creative LED modules require a more comprehensive preventive strategy. Teams schedule alignment inspections, thermal imaging, flexible circuit stress checks, and pixel calibration. Corrective maintenance may involve partial disassembly and software recalibration. Structured maintenance logs and predictive analytics help mitigate unexpected failures.

Standard LED module maintenance can be performed by general technicians with basic LED expertise. Creative modules require advanced skill sets, including experience with 3D geometry, flexible PCB handling, software diagnostics, and high-density pixel mapping. Manufacturers often provide specialized training programs to equip maintenance personnel. Investment in human capital ensures reliability and reduces the risk of inadvertent damage during service.

Maintenance differences between standard and creative LED display modules reflect their design philosophy and performance objectives. Standard modules provide predictable reliability with routine procedures, while creative modules deliver higher visual flexibility at the cost of specialized service. Facility managers and procurement teams must evaluate installation complexity, environment, and maintenance capabilities when selecting modules. With appropriate care, creative LED display modules achieve durable, high-performance output, maximizing return on investment and delivering captivating, immersive visual experiences.